Family Farm. Moshav Nir Israel.

A few kilometers from Ashkelon is Moshav Nir Israel. At the entrance to the moshav there is a stylized concrete cow symbolizing the main specialization of moshav. In this moshav live farmers who are engaged in dairy farming. Not all families are busy with this difficult business, but several strong farms produce milk, and very successfully.

On the example of one of these farmers, my old acquaintance Avry, I would like to talk about where the "milk rivers" come from. Such farms can be considered as typical family farms, which produce the main volumes of dairy products in the country.

Milk farm. Who on it and how much.

In the photo to the left - a classic representative of a dairy herd, consisting of 72 milch cows. This burenka with their friends, give annually 860,000 liters of milk. Simple arithmetic allows you to get the result: milk yield per 1 milch cow is about 12,000 liters of milk per year. This is the standard. If a cow gives less than 10,000 a year, it is considered that it is not cost-effective, as the cost of feed exceeds the revenue from the sale of milk.

In the photo to the left - a classic representative of a dairy herd, consisting of 72 milch cows. This burenka with their friends, give annually 860,000 liters of milk. Simple arithmetic allows you to get the result: milk yield per 1 milch cow is about 12,000 liters of milk per year. This is the standard. If a cow gives less than 10,000 a year, it is considered that it is not cost-effective, as the cost of feed exceeds the revenue from the sale of milk.

In addition to milking, the farm has 25 cows waiting for calves and 35 young animals.

The total number of cows is 132 cows and calves.

The bulls are for sale, and the calves are for replenishment of a dairy herd.

In the photo on the right - the younger generation.

We figured out the number of animals. And how many people need to take care of animals and produce more than 800 tons of milk per year?

We figured out the number of animals. And how many people need to take care of animals and produce more than 800 tons of milk per year?

The main thing on the farm is the owner, he is a manager, an accountant and a milkmaid, etc. etc. His name is Avri. Picture left.

The working day begins in the summer at 4 o'clock in the morning, in the winter at 5, and ends after the evening milking, that is at 6 - 7 pm. In addition to him, there is one permanent hired worker on the farm and, as far as possible, his father is helped by two sons, Dror and Erez. Dror serves in the army, but in the Israeli army, weekends are a holy thing. Therefore, he can help his father a few hours a week. And Erez helps in his free time. That's all the staff. Parents Avri, Yuda and Rachel, who at one time created this farm, and they began to farm in 1950, grew vegetables. Then they started with a single cow and in the end, by the beginning of the 70s of the last century, the specialization of the farm became dairy.

How do they manage to cope with such an economy? Everything is very simple. The correct organization of labor, technology and experience helps.

What and how to feed the little bumpkin.

To get 12 thousand liters of milk from a cash cow, you need to take care of its proper balanced and nutritious food. This computer is assisted by a computer that allows you to calculate the desired diet from the available components, and if problems or questions arise, you can always contact a qualified consultant from the Livestock Association or the Ministry of Agriculture. Consultancy assistance to farmers is very effective in the country, and farmers are willing to seek help from specialists if they have problems or questions.

There are two options for providing animals with feed. It is possible to order ready feed mixtures that will be brought to the farm at the set time and in the required quantities, or you can prepare the feed yourself. Avri buys all the necessary components of feed, and roughage and silage are harvested from him in advance and stored on the farm.

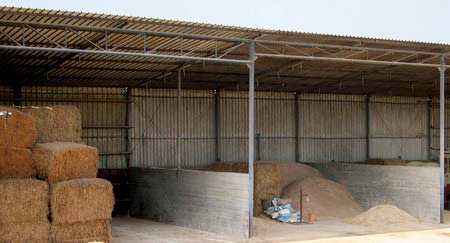

Feed stored under a canopy. Bales of hay, straw, components of concentrated feeds - ground grain, corn, meals in separate heaps and in bags - mineral and vitamin supplements.

Silo (left) is stored in concrete structures, and on top is covered with special synthetic material, protecting it from rain and sun (center). What ingredients and how to properly add them, in what proportions to make a feed mix for the herd, helps this leaf, which the farmer always has with him. In addition to the feed value of the various components and the required number of them, the table indicates prices. Thus, the farmer knows how much he spent today on feed in monetary terms. That's how the operational balance of costs and revenues is constantly monitored.

Feeding station on wheels.

In the feeding of animals there are two things: the preparation and distribution of food. Israeli engineers put the food shop on the wheels and combined the preparation and distribution of feed in one self-propelled unit.

Here such a self-propelled unit prepares and distributes food (photo left). The screw feeder feeds all components of the feed, including concentrated, coarse feed and silage to the mixing hopper (photo in the center). All components of the feed are automatically weighed and the weight of each loaded component is displayed on the screen of the minicomputer installed in the driver's cab (photo on the right). Thus, the farmer easily controls the weight ratio of all components of the feed and loads exactly the required amount of each component into the hopper.

In the hopper feeds are evenly mixed with a special auger mixer with knives to grind roughage (photo left). Cattle breeders know what a danger for animals is represented by metal objects that may accidentally end up in the stern. To protect against such "accidents" at the dispensing outlet of the mixing hopper, special tools are equipped with powerful magnets. These magnets catch from the food accidentally got into it metal objects. In the photo in the center, a circle is surrounded by a metal chip, which the magnetic trap clearly caught in the previous batch of food being handed out.

The use of such a "feeding station on wheels" saves time, resources and labor. In short - reliable, profitable, convenient.

Milk.

Milk - this is the very end product for which this farm exists.

72 milk cows, which for a year give almost 15 railway milk cisterns - it is very even good for farming. Avri could expand it, but there is a problem. This is the problem of selling products. All dairy producers in Israel have quotas for milk production. For the Avry farm, this quota is 800,000 liters of milk per year. What does this mean?

This means that he can sell 800 tons of milk at a price of 1.7 shekels per liter. Each liter of milk produced in excess of the quota, he will buy for only 0.45 shekel per liter.

Quotas the dairy market of the country is regulated and protected from overproduction. On the one hand, this limits the growth of farms, on the other hand, it allows to stabilize prices and production volumes.

Milking.

Equipment, which is used in the farm, can be called almost museum. This equipment is already about 30 years old. Nevertheless, it works well and milk is of good quality.

Milking parlor, if this half-open canopy can be called so, is designed for simultaneous milking of 16 cows. Although the milking machines look rather primitive, nevertheless, the equipment corresponds to all the standards accepted in the country, has a computer system for accounting for the amount of milk, identification of cows and determining the basic quality indicators.

Milk is filtered and enters two stainless steel tanks equipped with a milk cooling system.

The farmer has a contract with the Israeli company "Tnuva" to supply milk, and the milk company of the company takes milk from him daily.

This is the country's market is provided with milk, from which dairy plants produce more than 200 types and varieties of dairy products. The origins of dairy rivers.